The Benefits of Continuous Silo Level Measurement

In this article, Tredecile looks at some of the current challenges in continuous level measurement and offers an insight into the advantages of continuously monitoring the fill volume of your containers.

Challenges of Continuous Level Measurement

How you calculate the content of your silos depends on the materials in storage (bulk solids, powders, liquids, etc.) and the scale of your operations. Commercial agricultural crop systems, for instance, store enormous volumes of grain in tower silos where fill level is often estimated by manual, visual inspection. Expert workers may be able to gain a reasonable understanding of content volume by climbing up silo structures and inspecting the interior of the silo from the top down. Yet, this method poses health and safety concerns while failing to meet precise measurement objectives.

Implementing a continuous level measurement solution that automates this process can improve both workplace safety and inventory management objectives. Process managers increasingly utilize modern technologies for stock monitoring purposes. However, selecting the right level measurement solution for your silos poses its own challenges. What sensor technology can accurately monitor the level of your medium? Do you need a solution that measures fill volume continuously or periodically?

Choosing a Continuous Level Measurement Solution

There are many different continuous level sensors available for large grain silo fill volume measurements, alongside smaller feed bins. Capacitive sensors monitor the change in capacitance between two electrodes as a function of container level changes, but they are highly sensitive to various process conditions (humidity, temperature, etc.). Likewise, ultrasound sensors offer a fairly accurate measurement of container volume by assessing the time taken for ultrasonic signals to reverberate back to the sensor. These signals may be disoriented due to sound bouncing off the container internal walls and perturbed by airborne particulates/dust in the headspace, leading to measurement inaccuracies.

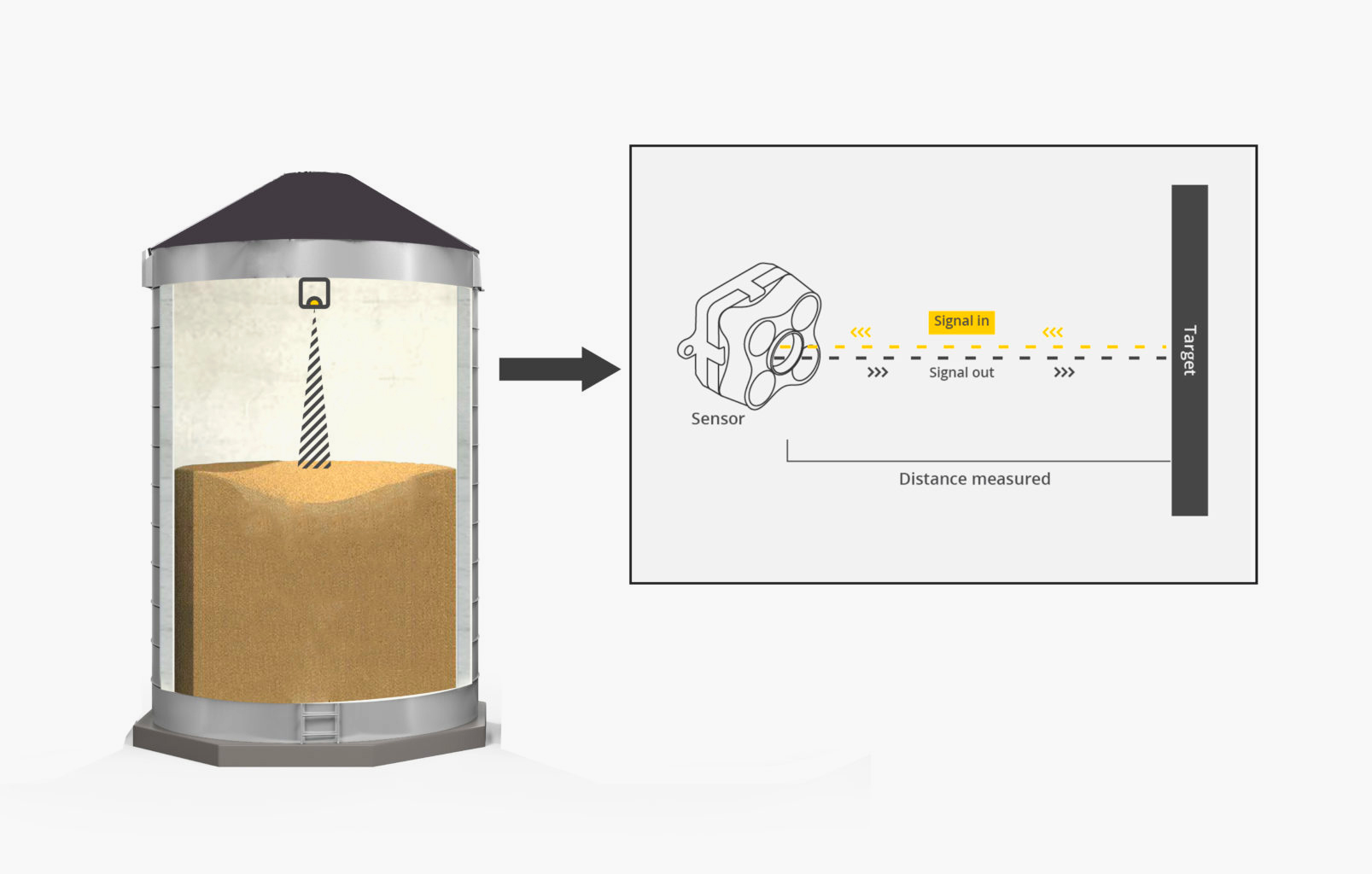

Infrared Time-of-Flight (ToF) sensors are among the most competitive continuous level measurement solutions for systems of all sizes. Unlike the previous sensor technologies discussed, they are truly advantageous from a price-to-performance perspective, significantly outstripping ultrasonic sensors in terms of accuracy with lower up-front costs than the likes of laser-based sensors and guided wave radar.

Continuous Level Measurement Products from Tredecile

Tredecile is one of the most innovative European sensor manufacturers with a division now focusing on continuous level monitoring in small, medium and large scale silos for agriculture, but also other markets! With a suite of IR-based ToF sensors for container fill level measurements, we can help you meet your unique stock management objectives. Currently, our leading distance sensor module for silo measurements is the TeraRanger Evo 60m, a long-range distance sensing platform suitable for continuous volume estimation and monitoring. We also offer the TeraRanger Evo 3m for closer range monitoring in smaller tanks (0.1 – 3m) and the TeraRanger Evo Mini ToF sensor, ideally suited to even smaller containers.

Self-powered, LoRaWAN level device

Tredecile’s pioneering LoRa Level Monitoring XL, a completely unique product designed to satisfy the needs of users across a broad spectrum of level monitoring applications. Based on a tried-and-tested Time-of-Flight LED technology, LoRa Level Monitoring XL is a wireless, self-powered and convenient to use continuous level measurement solution, transmitting level data directly from silos, using LoRaWAN.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.

Contact us to learn more about our upcoming product for smarter agricultural processes.