What is a level sensor?

Over the last 50 years, we’ve seen a wide variety of different level sensing devices introduced to the market. These range from simple float switches to capacitive sensors to wireless optical devices like Tredecile’s LoRa Level Monitoring XL.

In this blog post, we help to provide a simple answer to the question of what a level sensor is; taking you through the key principles of level sensing and explaining why different level sensor technologies are better suited to certain applications.

Point level vs. continuous

The most important distinction to make when categorizing a level sensor is that between point level sensors and continuous sensors.

A point level sensor only produces a signal when the fill level inside a container crosses a certain threshold. This type of level sensor remains popular for some limited applications – but they’re not suitable for use in situations where knowing the actual amount of material in a container is critical. Common point level sensors include float switches and vibrational probes.

Continuous sensors are the more accurate and informative of the two: this type of level sensor takes quantified fill level measurements at regular time intervals. As well as providing more accurate data at any given moment, continuous sensors provide a record of fill level over time. This historical data gives valuable insight into inventory behavior, enabling accurate forecasting and effective stock management.

Invasive vs. non-invasive

Another important consideration to make when choosing a level sensor for a certain application is whether it is an invasive or non-invasive technology.

Invasive sensors are those which must physically come into contact with the stored medium in order to measure fill level. This may involve:

- Integrating sensing elements into the tank itself (all resistive sensors and some hydrostatic sensors)

- Submerging a sensor in the medium (submersible hydrostatic sensors)

- Floating a magnet on top (float sensors)

Invasive technologies are unsuitable for applications where the stored medium is sensitive (e.g., foodstuffs) or aggressive (e.g., highly acidic or alkaline).

Ease of installation

Cabling, mounting options and requirements for specialist installation are all factors that can influence the choice of level sensor for different IoT applications.

Some types of hydrostatic level sensor must be installed in outlet ports or at the bottom of a tank. This results in high initial costs and can also make repairs difficult in the event of a fault with the sensor.

Many types of sensor (capacitive and resistive sensors, for example) at a minimum require that the tank or silo is fully emptied for installation. Most sensors also require cabling, both for power and data transmission. Depending on the height of containers or the scale of operation, cabling costs can dramatically increase installation costs.

Versatile, continuous level sensors from Tredecile

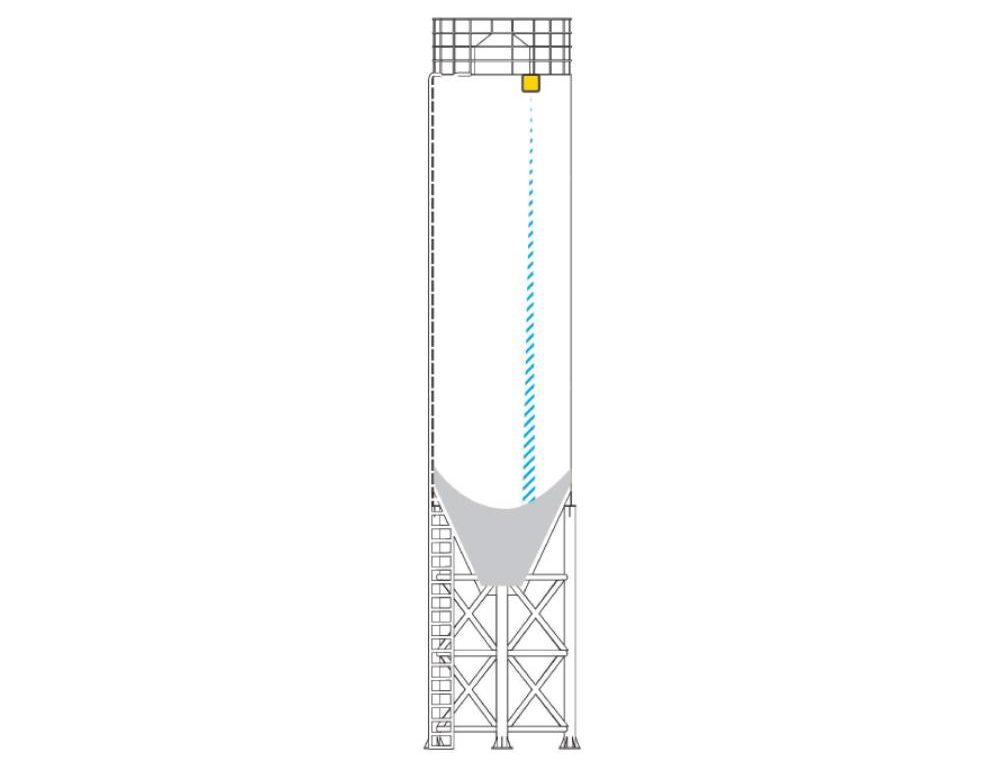

Tredecile developed the LoRa XL level sensor to simplify fill level sensing. Using optical ToF technology, Tredecile sensors provide accurate non-contact fill level detection for containers between 0.5 m and 60 m in height. Completely battery-powered, Tredecile level sensors require no cabling or specialist installation: simply mount the device at the top of a container and easily calibrate it via any web-enabled device. Tredecile IoT level sensors use LoRaWAN for low-power long-range data transmission, enabling users to stream live depth information or adjust settings on the go.

Get in touch with us to find out more about our unique level sensing solutions.