From farmers stocking animal feed in silos providing livestock with a daily dose of healthy nutrition, to manufacturing plants needing to ensure an amount of raw material enters the production line to output final goods. All those dealing with material stock need answers to the same questions:

• How much raw material or stock do I have left, right now?

• When best to plan stock replenishment?

• Is my material storage equipment being used effectively?

Tredecile has been working on a smart stock monitoring system to help companies digitize their bin levels, and enable users to benefit from real-time and historical data of remaining material stock. Results are a reduction in operational costs and improvements to overall safety!

• How much raw material or stock do I have left, right now?

• When best to plan stock replenishment?

• Is my material storage equipment being used effectively?

Tredecile has been working on a smart stock monitoring system to help companies digitize their bin levels, and enable users to benefit from real-time and historical data of remaining material stock. Results are a reduction in operational costs and improvements to overall safety!

What does the Tredecile Stock Level Monitoring System offer?

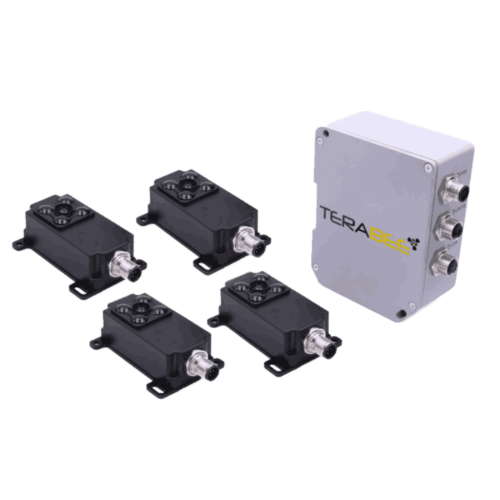

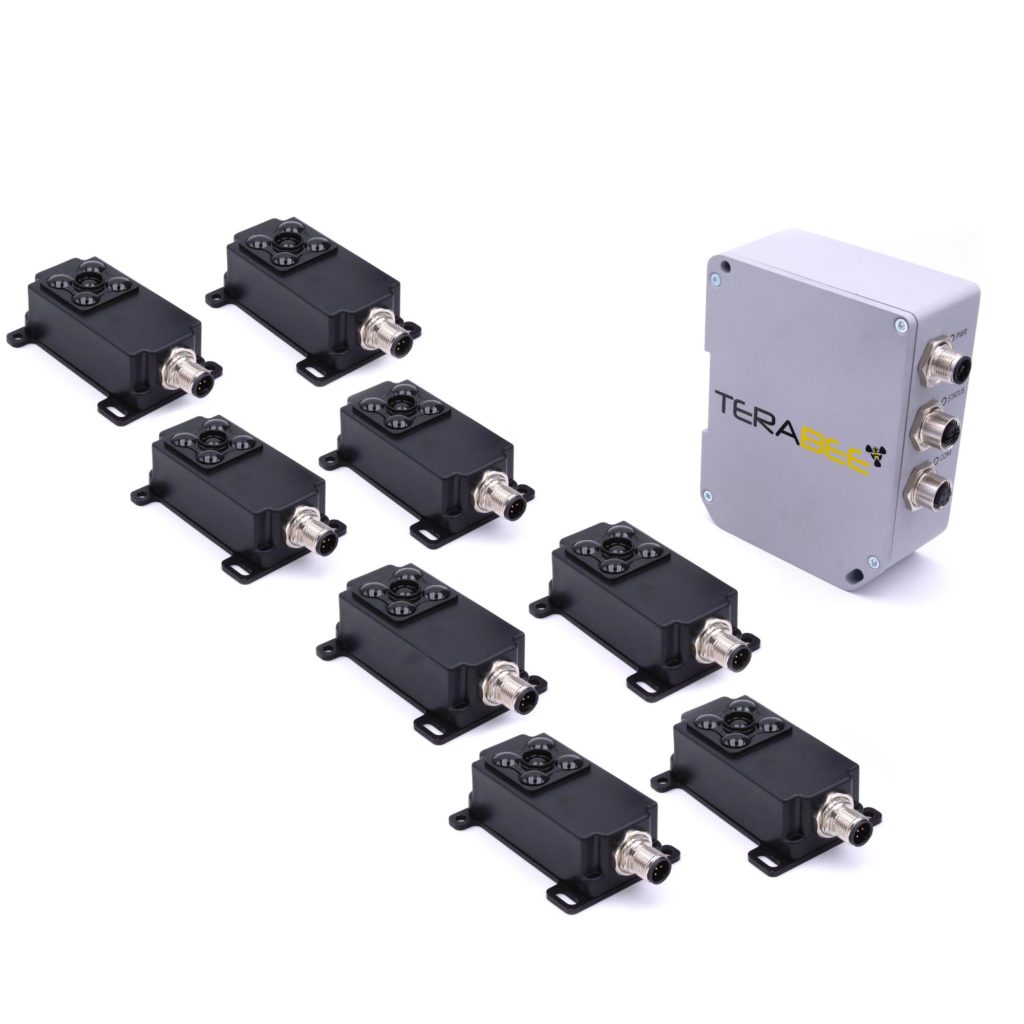

Tredecile has released its bin level monitoring system enabling users to measure continuous material fill level and estimate volumes of remaining stock. The system has 3 major components: (1) Stock Level Sensor, (2) Stock Level Supervisor (central computing unit), and (3) Web-based configuration tool.

Rugged, high performance Time-of-Flight sensors are installed on top of containers or stockpiles, with up to 60 metre detection range. Sensors are then connected to the central computing unit via RS485, and raw distance-to-material data is collected from each sensor. The Stock Level Supervisor supplies power to all sensors, and features embedded computation functions - turning incoming distance data into level or volume estimations of the remaining material stock. The Stock Level Supervisor is connected to a Programmable Logic Controller (PLC) for further data communication (Ethernet) and data processing.

Rugged, high performance Time-of-Flight sensors are installed on top of containers or stockpiles, with up to 60 metre detection range. Sensors are then connected to the central computing unit via RS485, and raw distance-to-material data is collected from each sensor. The Stock Level Supervisor supplies power to all sensors, and features embedded computation functions - turning incoming distance data into level or volume estimations of the remaining material stock. The Stock Level Supervisor is connected to a Programmable Logic Controller (PLC) for further data communication (Ethernet) and data processing.

System Specifications

STOCK LEVEL SUPERVISOR

• No. of sensors connected: up to 8 (extension for up to 32 sensors)

• Data Interface: Ethernet (Modbus TCP/IP), Wifi

• Supply Voltage: 24V DC +/-10%

• Dimensions, Weight: 110 x 121 x 45 mm, 205 g

• Protection: IP65

• Software support: Embedded configuration tool (web-based)

STOCK LEVEL SENSOR

• Detection principle: Optical Time-of-Flight (infrared)

• Range: 0.5m up to 60m (dark conditions)

• Field of View, per sensor: 2 degrees

• Interface to Stock Level Supervisor: RS485 (Modbus)

• Dimensions, Weight: 94 x 56 x 31 mm, 99g

• Protection: IP65

• No. of sensors connected: up to 8 (extension for up to 32 sensors)

• Data Interface: Ethernet (Modbus TCP/IP), Wifi

• Supply Voltage: 24V DC +/-10%

• Dimensions, Weight: 110 x 121 x 45 mm, 205 g

• Protection: IP65

• Software support: Embedded configuration tool (web-based)

STOCK LEVEL SENSOR

• Detection principle: Optical Time-of-Flight (infrared)

• Range: 0.5m up to 60m (dark conditions)

• Field of View, per sensor: 2 degrees

• Interface to Stock Level Supervisor: RS485 (Modbus)

• Dimensions, Weight: 94 x 56 x 31 mm, 99g

• Protection: IP65

Web-based configuration tool

Tredecile Stock Level Monitoring includes a web-based configuration tool with easy to follow steps for setting up your application. Simply feed the application with information, like container dimensions and shape, material type, number of sensors used, preferred sensor position and more! Each parameter is used to improve the stock volume and level calculation algorithms and output accurate application data.

Potential applications

Suitable for measurements of liquid, powder and solid materials, our first iteration will enable users access to the capabilities of bin level monitoring and volume measurements using optical Time-of-Flight technology.

Tredecile offers its customers maximum flexibility as the system allows them to evaluate a number of monitoring configurations. For liquid materials or containers with known material surface distribution we suggest using a single sensor setup. Whereas for larger spaces with unpredictable material distribution, multiple sensor installations will allow for more accurate volume estimations.

Users can also perform multi-container measurements for grouped bins, using a single Stock Level Supervisor.

Tredecile offers its customers maximum flexibility as the system allows them to evaluate a number of monitoring configurations. For liquid materials or containers with known material surface distribution we suggest using a single sensor setup. Whereas for larger spaces with unpredictable material distribution, multiple sensor installations will allow for more accurate volume estimations.

Users can also perform multi-container measurements for grouped bins, using a single Stock Level Supervisor.

From a PoC project to an industrialised product

Tredecile’s stock level monitoring concept was born in a brick manufacturing plant, while working with one of our clients to support them in their journey to automate their supply and production processes. Along the way, a few challenges were identified.

• Visual stock inspections by factory staff can be time-consuming and result in a fixed labor cost, with the need for regular evaluations of remaining stock in containers.

• Manual checks also present real risks of fall and injury, especially for larger containers requiring operations at considerable heights.

• In addition, manual material approximations can lead to inaccurate data and introduce significant inefficiencies for stock replenishment. This includes running out of raw material blocking production capabilities, or receiving stock deliveries too early without available safe storage.

Tredecile prototyped and installed a multi-sensor bin level monitoring system with a robust connection to a factory PLC for further programming. Real-time data on material fill levels enabled the client to control raw material entry into the production process, and provided an accurate overview of stock in storage containers. Accumulated data overtime allowed for a better understanding of consumption cycles, enabling optimization of stock resupply. The project demonstrated positive outcomes, with a further need for solution industrialization!

• Visual stock inspections by factory staff can be time-consuming and result in a fixed labor cost, with the need for regular evaluations of remaining stock in containers.

• Manual checks also present real risks of fall and injury, especially for larger containers requiring operations at considerable heights.

• In addition, manual material approximations can lead to inaccurate data and introduce significant inefficiencies for stock replenishment. This includes running out of raw material blocking production capabilities, or receiving stock deliveries too early without available safe storage.

Tredecile prototyped and installed a multi-sensor bin level monitoring system with a robust connection to a factory PLC for further programming. Real-time data on material fill levels enabled the client to control raw material entry into the production process, and provided an accurate overview of stock in storage containers. Accumulated data overtime allowed for a better understanding of consumption cycles, enabling optimization of stock resupply. The project demonstrated positive outcomes, with a further need for solution industrialization!

Interested in digitising your stock levels?

Contact us to discuss your application and learn more about the stock level monitoring system - we are in the final stages of industrialisation and solution validation. Please note that presented system specifications can be subject to change.

We welcome collaboration from partners looking for innovation in digital stock management and can offer PoC engagements for you to assess the potential and full benefits of Tredecile Time-of-Flight technology. Our processes are lean, iterative and reduce risk for innovation projects. Get in touch today!

We welcome collaboration from partners looking for innovation in digital stock management and can offer PoC engagements for you to assess the potential and full benefits of Tredecile Time-of-Flight technology. Our processes are lean, iterative and reduce risk for innovation projects. Get in touch today!

Self-powered, LoRaWAN level device

Meet Tredecile's pioneering LoRa Level Monitoring XL, a completely unique product designed to satisfy the needs of users across a broad spectrum of level monitoring applications. Based on a tried-and-tested Time-of-Flight LED technology, LoRa Level Monitoring XL is a wireless, self-powered and convenient to use level monitoring solution, transmitting level data directly from silos, using LoRaWAN.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.