Real time level monitoring for Nan-Ho Cooperative Farm, Taiwan

We are delighted that following a three month evaluation of our bin level monitoring system, Nan-Ho Cooperative Farm in Taiwan, will be rolling our Stock Level Monitoring System across its entire facility, incorporating more than 70 grain silos.

The requirement

Nan-Ho Cooperative Farm stores its harvested rice and corn in 16m high silos. Levels within the containers were being monitored by rotary paddle level switches. This system relies on a paddle being impeded by the product being stored within the container. When the paddle comes into contact with the product, the motor stalls and the micro-switch indicates a change of state.

The rotary paddle level switch system did not provide accurate and real-time data on container levels. As a result, staff were having to perform regular visual audits to confirm remaining levels within each silo, but also manually control material emptying from the silo. This required staff to climb to the top of each silo – which was not only time consuming, but potentially dangerous.

Introducing Tredecile’s Stock Level Monitoring System

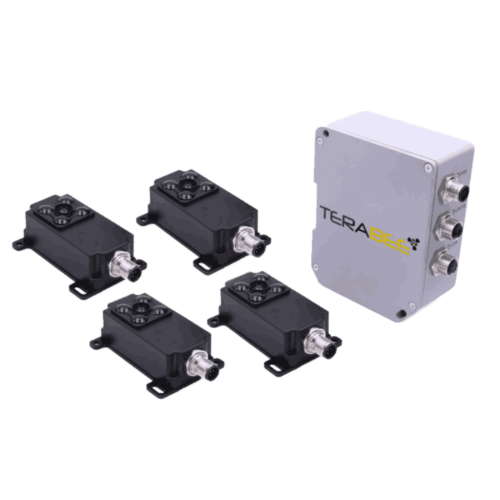

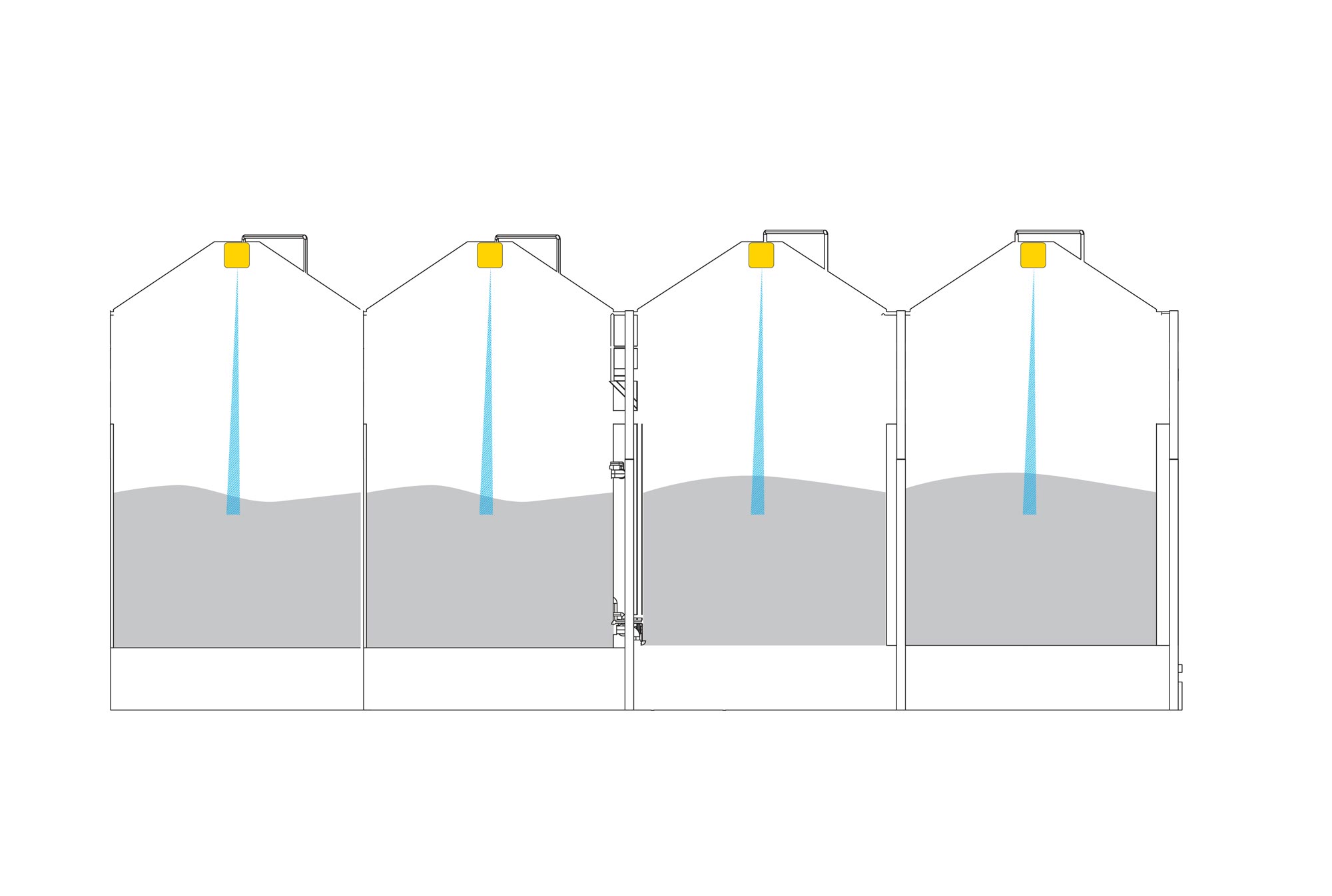

Tredecile has been working with Nan-Ho Cooperative Farm to deliver a more accurate, reliable and less intrusive bin level monitoring solution. Our silo level monitoring systems are based on optical Time-of-Flight (ToF) sensor technology. The solution we proposed for Nan-Ho included a multi-sensor monitoring system with a single ToF sensor installed at the top of each silo, each of which is connected to a central hub unit (the Supervisor unit).

The sensors, which are lightweight (99 grams), can detect level measurements within a range of up to 60 meters and are wired to the Supervisor unit via RS458 interface. The Supervisor unit provides power to each connected sensor and triggers sensors in a sequence in order to collect distance measurements. It also performs real-time computation of the remaining levels, and outputs the data reading to a local PLC unit via Ethernet (Modbus TCP/IP) interface.

Stock level monitoring at Nan-Ho

Nan-Ho Cooperative Farm trialled a four sensor configuration (connected to a Supervisor unit) on four silos over a three month period. Our system was integrated with a PLC unit that displays remaining bin level data from each silo on the client IoT application software, which is made available via PC and on mobile devices.

The system delivers real-time data monitoring of silo levels – which can be viewed from multiple devices, anytime, anywhere. This minimizes the need to climb the silos to conduct visual audits of product levels, which is only far safer and has improved the farm’s operations as it leaves staff free to perform other tasks.

What’s more, because levels are measured every minute, any sudden level changes that might be caused by a leak or by overfilling can be quickly detected and remedied, thereby minimizing damage. Tredecile’s ToF sensors deliver further advantages – they are unimpeded by the dust particles within the environment, and they also minimize contamination risk as they do not come into physical contact with the rice or corn within the silos.

Wu Chenen, Managing Director, Nan-Ho Cooperative Farm commented, “We have been very impressed with Tredecile’s stock level monitoring system. We were able to set-up and trial the system with minimal remote support. The Supervisor unit automatically triggers data collection, and the on-board web application delivers seamless system configuration – making the setup process and integration very easy.”

Benefits at a glance

- Improved staff safety and reduced operations costs

- Accurate, real-time bin level monitoring data

- Long-range monitoring capability

- Simple, intuitive system configuration and integration

- Compact, lightweight sensors

- Sensors unimpeded by dusty environment

- Non-intrusive therefore no contamination

- Minimal physical/visual intervention required

“Thanks to Tredecile we can now monitor the levels in our silos in real-time and with precision accuracy – and with minimized need for physical staff intervention. The system offers superb value as it is extremely competitively priced, and the Tredecile team have consistently provided timely and professional advice and support. “ Wu Chenen, Managing Director, Nan-Ho Cooperative Farm

Next steps

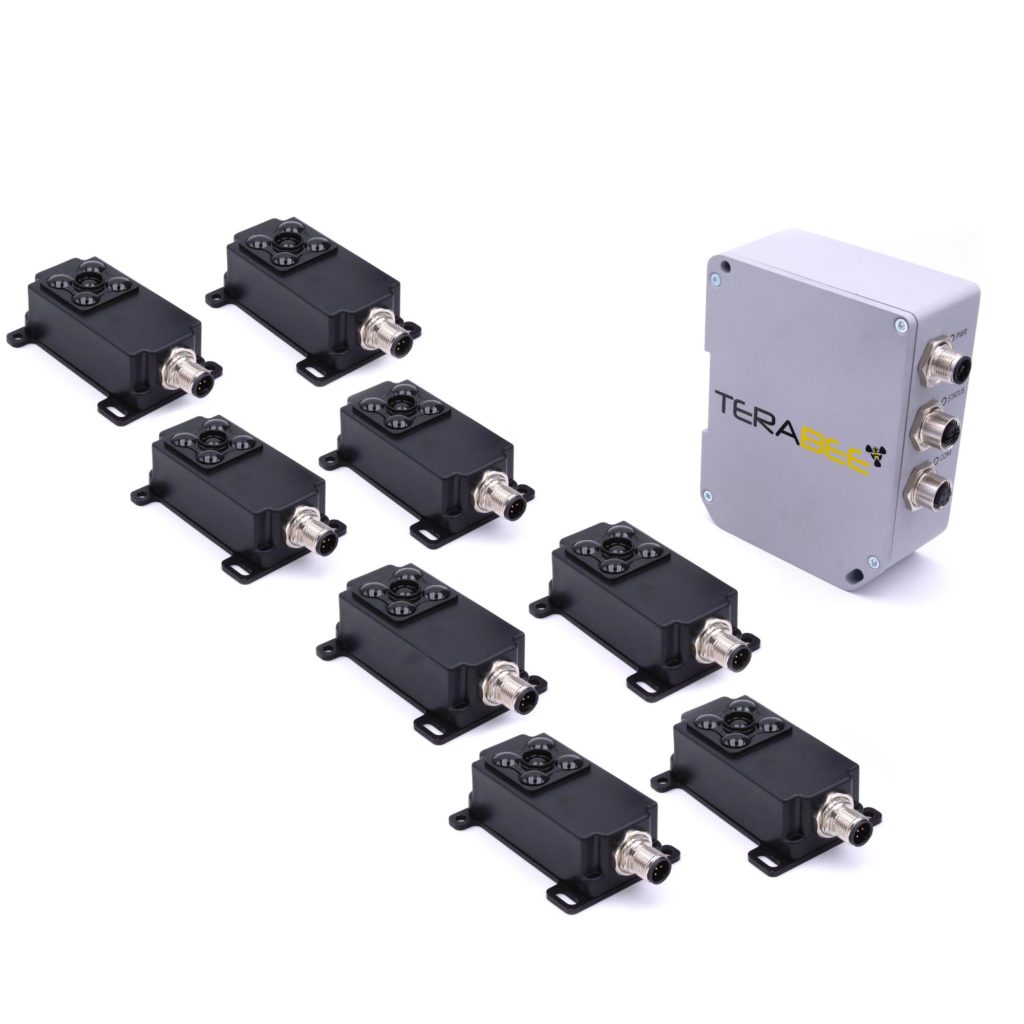

Following successful completion of the trial, Nan-Ho is rolling out Tredecile’s stock level monitoring system across its entire facility, incorporating more than 70 rice and corn silos. The Cooperative Farm is currently finalising construction of another silo plant which is planned to be equipped with Tredecile’s ToF sensors on completion.

The system has also received great interest from local authorities in Taiwan, including the Agriculture and Food Agency and the Council of Agriculture, and we look forward to working with these agencies to promote the system and deploy it in other agricultural sites across the country.

Contact the Tredecile team to discuss your bin level monitoring project or read more about our Stock Level Monitoring System.