Top Sensor Types Used in Silo Level Monitoring

All of this data collection relies on the use of sensors. There are many different types of sensing technologies in the market – made for different purposes, including temperature, humidity, light, audio, GPS, level sensors, and more. Each of these allows us to remotely monitor a number of conditions associated with specific assets. Audio sensors, for instance, are increasingly used to monitor the overall health of beehives and predict honey harvesting periods reducing unnecessary interactions with bees. Inertial measurement unit (IMU) sensors, a combination of an accelerometer and gyroscope that checks for movement, is a way of detecting events such as thefts, vandalism, or other unexpected happenings of certain assets. In animal feed silos, for instance, humidity and temperature sensors enable monitoring of grain quality to avoid spoilage of feedstocks, while level measurement sensors help farmers and feed suppliers predict feed material resupply and optimize the delivery process.

While the overall demand for sensors in IoT applications keeps growing, the need for remote level and volume monitoring is particularly picking up.

Why Are Level Measurements Important?

For many applications, including level measurements in silos, there are many advantages to have sensors interfaced with wireless monitoring. This is part of why there is a growing global demand for remote level data monitoring over the internet. Remote monitoring is cost-effective in comparison to regular manual inspections and can also improve workplace safety, as it eliminates potential risks and injuries associated with performing manual inspections.

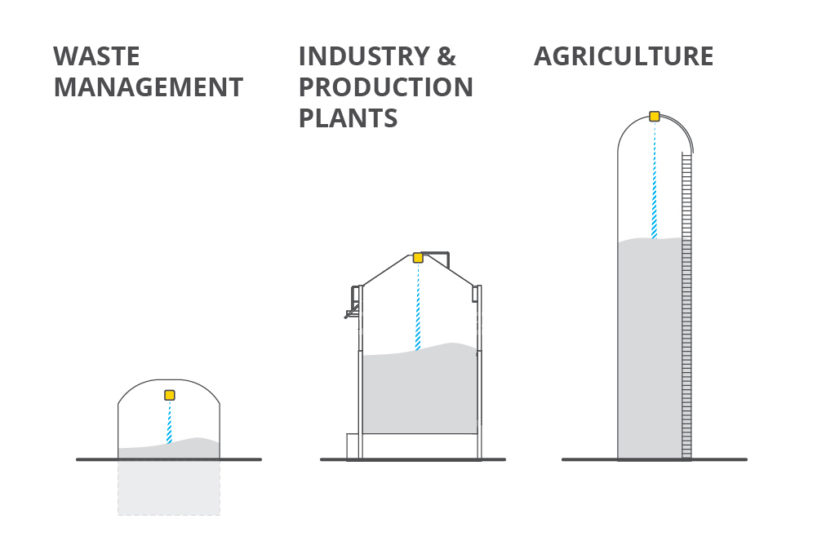

As well as grain silos, remote measurements can be used in waste bins, animal feed silos, construction materials, and on water surfaces. Wireless data monitoring means that companies can not just monitor stock levels, but make advanced plans for stock replenishment or material collection, optimizing their budget and logistics operations.

Remote and real-time data monitoring means that, if quick decisions need to be made, decisions can be underpinned by suitable data, such as on water levels during flooding events.

Level Monitoring

Over the years, a number of sensors have been used to monitor levels inside containers, silos, bins, and tanks. These sensors are usually divided into contact-based level transmitters, including capacitive, measurement tape systems, float; and non-contact transmitters, including radar, ultrasound, and laser. Contactless level sensors have become more popular in the last few years, mostly because these provide non-intrusive measurements with no direct contact with monitored materials, require less maintenance, and offer great value for money!

Similar to how an ultrasound signal detects how full a storage bin is (the time taken for the reflected wave to return can be used to calculate the level of material inside a container), Tredecile deploys level monitoring sensors based on an optical Time-of-Flight principle. Using low-power infrared LEDs offers several advantages over other methods for level monitoring applications.

ToF measurements are non-intrusive, remote measurements that do not need to be in contact with monitored materials (e.g grain stock) to operate, unlike point level switches for grain levels that need to be immersed in the feed.

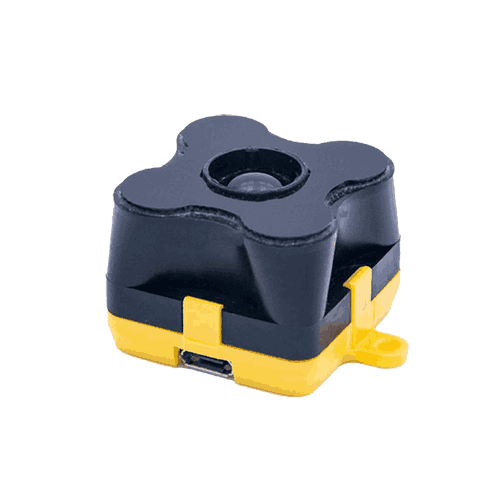

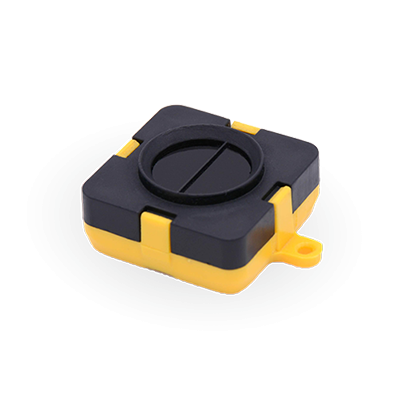

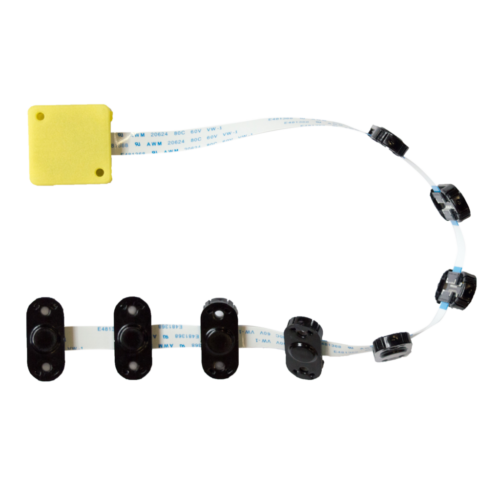

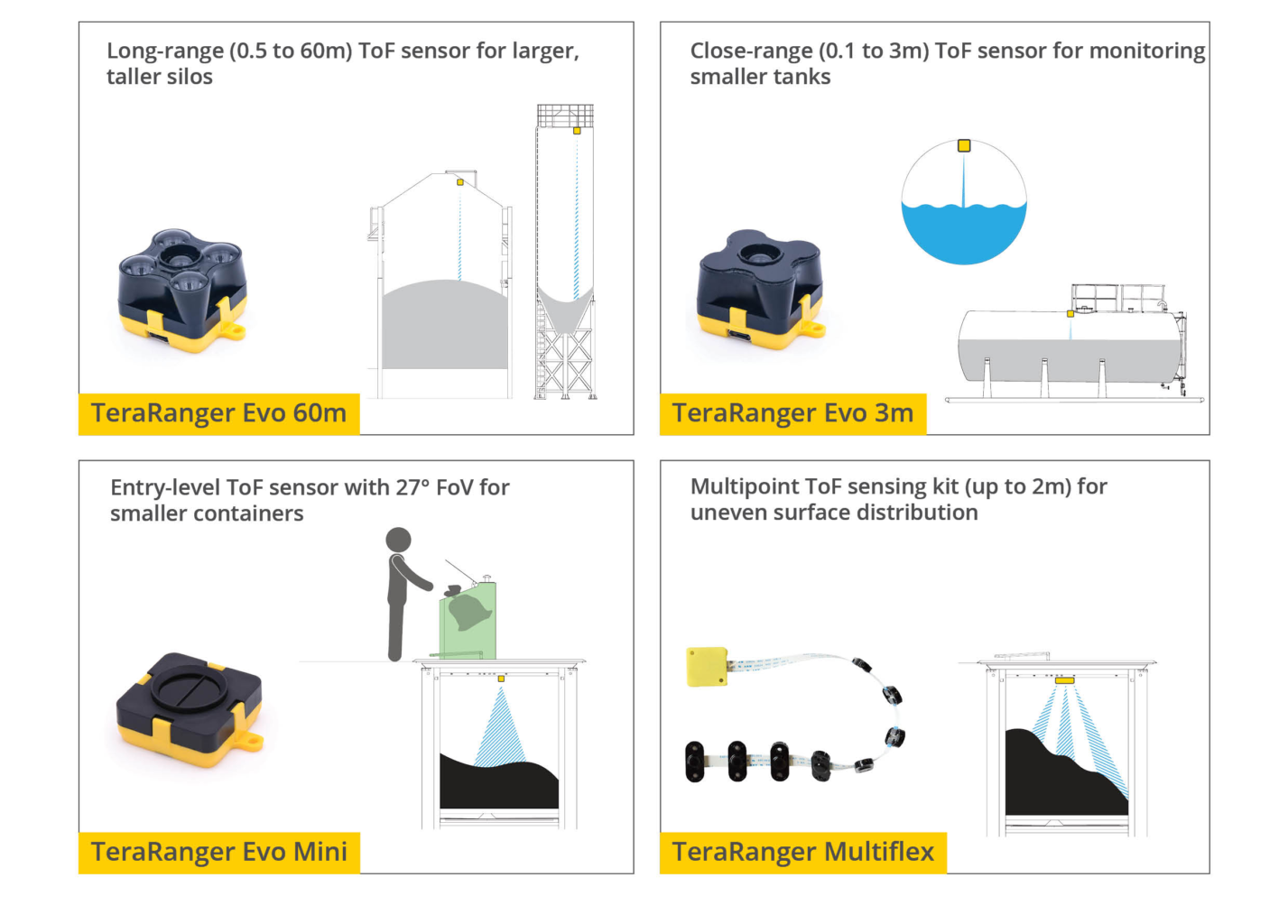

Depending on the size of the grain bin and material to be monitored, Tredecile offers several types of ToF sensor modules perfectly suited to system integration and OEM design-in projects. For small bins or confined spaces, the TeraRanger Evo 3m⁶ or TeraRanger Evo Mini would be the most appropriate as these provide accurate close-range distance measurement capabilities. As for larger bins, the TeraRanger Evo 60 m sensor would be the best choice capable of up to 60 meter detection range, maintaining a compact and low-cost design . If you’re looking for a more robust, standalone device that can be quickly installed inside your bin, Tredecile offers its IP65-rated sensor module – Tredecile IND-TOF-1 – with a 12.5m range.

As these level sensors are fully integratable with an IoT network or with a local computer, the information they provide can be used to plan and optimize stock replenishments and pickups, as well as bringing cost savings by eliminating the need for manual inspections. The sensors provide complete round-the-clock coverage, and the real-time data streams can mean up-to-date information is provided in critical situations such as dangerously low/high stock levels or flooding, where quick decisions are imperative.

All of Tredecile’s sensors can be easily interfaced with interfaces like RS485, USB, I2C, UART, or alternative networking formats making it possible to create a fully automated process, alarm, and feedback systems for material level monitoring and safety. Where complex customer requirements are needed or custom solutions, Tredecile also offers significant expertise in the field of sensor technologies and can provide both tailored technical and sales support.

Self-powered, LoRaWAN level device

Meet Tredecile’s pioneering LoRa Level Monitoring XL, a completely unique product designed to satisfy the needs of users across a broad spectrum of level monitoring applications. Based on a tried-and-tested Time-of-Flight LED technology, LoRa Level Monitoring XL is a wireless, self-powered and convenient to use level monitoring solution, transmitting level data directly from silos, using LoRaWAN.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.