Applications - Level measurement - Level monitoring

Continuous Level Sensors for Farming Silos

Smart farming is a farm management concept which makes use of modern technology to make farming more efficient. It doesn’t necessarily require huge investments in technology or analysis of large data sets – great improvements in efficiency can be made simply by implementing sensors to monitor stock and feed levels. Tredecile's versatile sensor modules are enabling IoT solution providers to offer digital continuous level data to farmers, cooperatives and feed suppliers - with simple, yet innovative, low-cost setups. In this article, we explore how real-time continuous level monitoring can not only save time and manpower, but improve safety, reduce waste, and inform data-driven business decisions.

A shift towards technology-driven practices in industry and manufacturing means the use of networked sensors is expected to increase. From automated guided vehicles in warehouses to digital level monitoring in manufacturing plants; the use of continuous level sensors enables businesses to immediately capture a snapshot of the physical parameters that influence their operations, as well as enabling automated decision making. The interconnection of everyday objects in this way has become known as the Internet of Things (IoT), and is expected to change the way businesses operate throughout the 21st century. The collection of data from embedded sensors, in tandem with in-depth analysis, can enable businesses to optimize decision-making processes.

Farming is no different. While agriculture, of course, predates most (or, arguably, all) industries, this doesn’t mean it’s immune to modern technology. On the contrary, agriculture is seen as ideally suited to large-scale data collection and analysis. Agricultural processes and equipment are also undergoing radical changes in the face of advancing technology: the first self-driving tractors are already plowing the fields of San Francisco, and drone technology is being successfully employed for the monitoring of crop health.

But making use of modern technology in agriculture doesn’t necessarily require a large investment in complex technology such as drones, automated vehicles or big data analysis software. Instead, the strategic implementation of a few networked sensors can provide huge advantages to users simply by providing up-to-date information about stock levels, animal feed bins, and other agricultural containers.

Farming is no different. While agriculture, of course, predates most (or, arguably, all) industries, this doesn’t mean it’s immune to modern technology. On the contrary, agriculture is seen as ideally suited to large-scale data collection and analysis. Agricultural processes and equipment are also undergoing radical changes in the face of advancing technology: the first self-driving tractors are already plowing the fields of San Francisco, and drone technology is being successfully employed for the monitoring of crop health.

But making use of modern technology in agriculture doesn’t necessarily require a large investment in complex technology such as drones, automated vehicles or big data analysis software. Instead, the strategic implementation of a few networked sensors can provide huge advantages to users simply by providing up-to-date information about stock levels, animal feed bins, and other agricultural containers.

Common issues with Visual Level Inspection

Determining levels of feed and produce on farms by visual inspection presents a number of risks and challenges.

Primarily, it can be enormously time-consuming. Manual animal feed bin level monitoring, grain monitoring in silos and stock estimation of animal feed in stockpile spaces all take time and therefore have an associated labor cost.

Visual inspection is often inaccurate too. A lack of accurate and up-to-date information can have serious consequences when used for decision-making regarding stock replenishment. Realizing there is insufficient space for an incoming delivery or that you are unexpectedly unable to meet customer demand with existing stock are both problematic scenarios.

Primarily, it can be enormously time-consuming. Manual animal feed bin level monitoring, grain monitoring in silos and stock estimation of animal feed in stockpile spaces all take time and therefore have an associated labor cost.

Visual inspection is often inaccurate too. A lack of accurate and up-to-date information can have serious consequences when used for decision-making regarding stock replenishment. Realizing there is insufficient space for an incoming delivery or that you are unexpectedly unable to meet customer demand with existing stock are both problematic scenarios.

Replenishing stock too early, before previous material has been used up, can make it difficult to safely store deliveries. At the other end of the scale, unexpected stock depletion can require expensive emergency deliveries and put livestock wellbeing and agricultural production capabilities at risk. In addition, ineffective use of storage spaces and silos effectively increases equipment downtime: an empty silo is one that is not being used efficiently.

In addition to these issues; climbing up to the top of tall silos, hoppers, and bins to perform level inspections presents a very real risk of fall and injury to farmers. Out of 335,000 annual workplace deaths worldwide, over half occur in agriculture, making jobs in agriculture the most dangerous jobs in the world. Reducing the need for visual silo inspections will bring a much-needed improvement to workplace safety for farm workers.

In addition to these issues; climbing up to the top of tall silos, hoppers, and bins to perform level inspections presents a very real risk of fall and injury to farmers. Out of 335,000 annual workplace deaths worldwide, over half occur in agriculture, making jobs in agriculture the most dangerous jobs in the world. Reducing the need for visual silo inspections will bring a much-needed improvement to workplace safety for farm workers.

Versatile Low-Cost Continuous Level Sensors for Level Monitoring

To minimize these issues, more and more farms and feed suppliers are now deploying or subscribing to IoT platforms with measurement devices for smart silo continuous level estimations. As a result, demand is growing for the sensing component parts: temperature, humidity, pressure, including the most critical piece for stock estimation - the level sensor or distance sensor. Tredecile has a portfolio of high-performance and low-cost sensor modules, with the capacity to address a variety of applications within the farming industry, including continuous level monitoring.

Implementing continuous level sensors to monitor stock levels can have huge benefits for farms of any size. Networking these continuous level sensors enables farmers to instantly check the stock levels in all containers simultaneously, eliminating any requirement for visual inspection. This does away with the inefficiencies associated with a visual inspection, leaving farmers and personnel free to focus on the many other important tasks in the running of a farm.

Implementing continuous level sensors to monitor stock levels can have huge benefits for farms of any size. Networking these continuous level sensors enables farmers to instantly check the stock levels in all containers simultaneously, eliminating any requirement for visual inspection. This does away with the inefficiencies associated with a visual inspection, leaving farmers and personnel free to focus on the many other important tasks in the running of a farm.

As well as reducing inefficiencies and risks to business, livestock and personnel; using continuous level sensors to check stock levels has a number of other benefits. Continuous level monitoring and logging of data can enable farmers to make the best possible data-driven decisions regarding restocking, new equipment purchases, and other aspects of their business. Scheduling deliveries as efficiently as possible also means transport costs and CO2 emissions due to material delivery are minimized, and continuous level sensors can help to deal with security-related events such as leaks in silos which cause levels to unexpectedly drop.

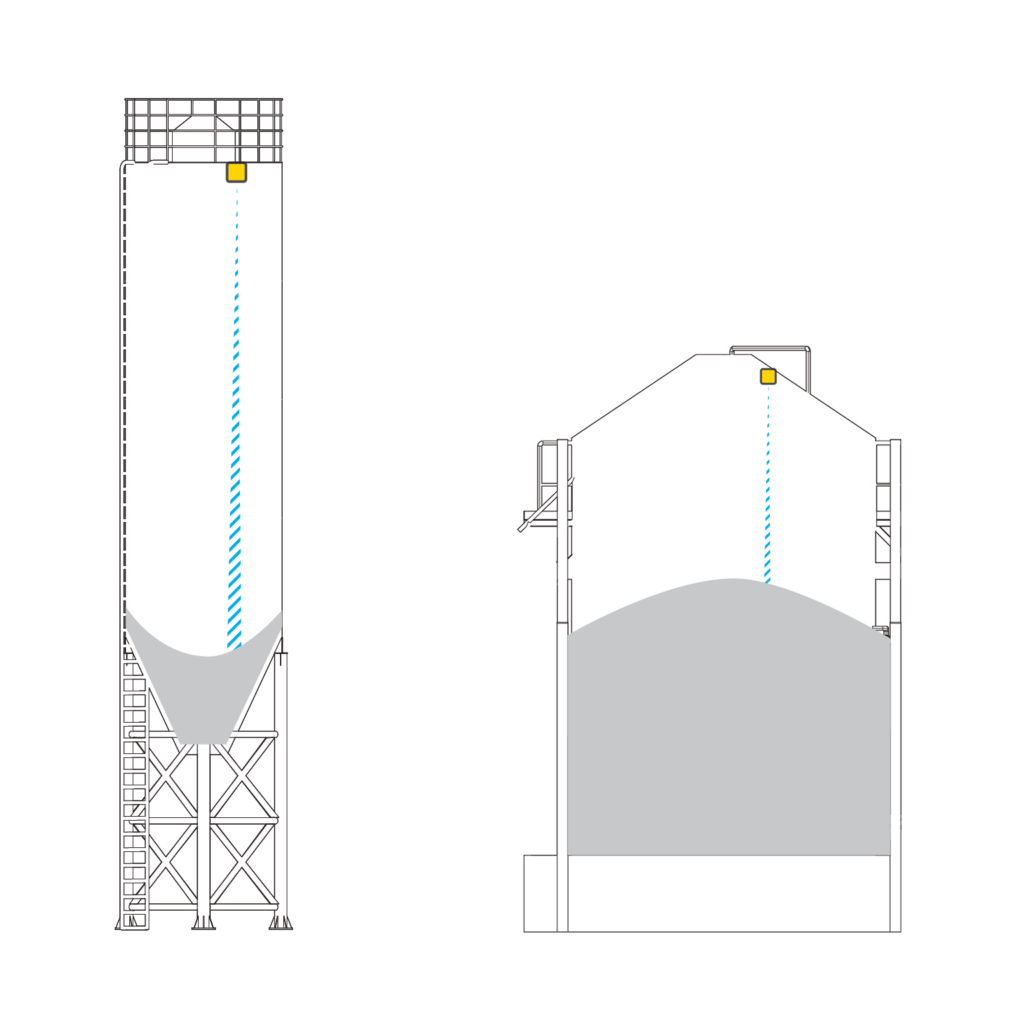

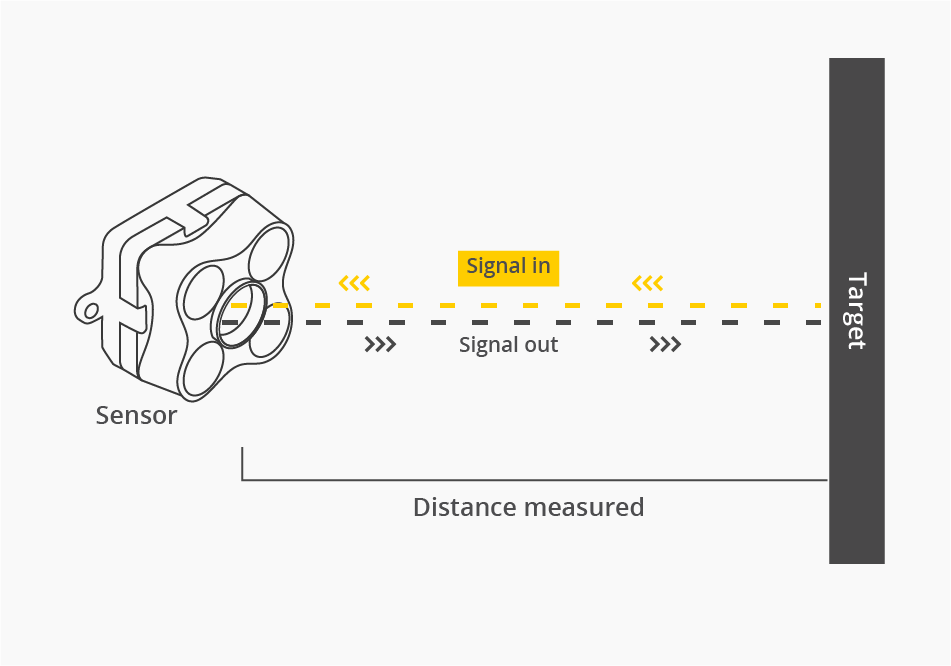

Tredecile’s continuous level sensors use optical Time-of-Flight (ToF) technology to sense distance. ToF sensors emit a beam of invisible infrared light and measure the time taken for it to reflect from the surface of the stored material using precise timing circuitry. This enables the accurate calculation of stock levels in hoppers, bins, and silos of any size; even in dusty environments such as grain silos.

Tredecile’s continuous level sensors use optical Time-of-Flight (ToF) technology to sense distance. ToF sensors emit a beam of invisible infrared light and measure the time taken for it to reflect from the surface of the stored material using precise timing circuitry. This enables the accurate calculation of stock levels in hoppers, bins, and silos of any size; even in dusty environments such as grain silos.

Benefits of Using Optical ToF LED Technology

• Contactless measurements avoids content contamination

• High-performance in a cost-effective format

• Long-range measurements (up to 60m) for taller containers

• Ideal solution for integration and design-in projects

• Low power consumption – great for battery devices

• Focused 2 degree Field-of-View suited to confined spaces or narrow containers

• Multi-sensor solutions for monitoring uneven surface distribution

• Higher performance alternative to ultrasound; and lower-cost alternative to laser and radar

• High-performance in a cost-effective format

• Long-range measurements (up to 60m) for taller containers

• Ideal solution for integration and design-in projects

• Low power consumption – great for battery devices

• Focused 2 degree Field-of-View suited to confined spaces or narrow containers

• Multi-sensor solutions for monitoring uneven surface distribution

• Higher performance alternative to ultrasound; and lower-cost alternative to laser and radar

Level Monitoring Solutions for Integration from Tredecile

Tredecile offers a range of high-performance and continuous level sensors for monitoring stock and fill levels in silos and other containers. These are available today for order, evaluation, and OEM integration projects - with a market-leading price versus alternative measurement solutions, including ultrasound, radar, and laser.

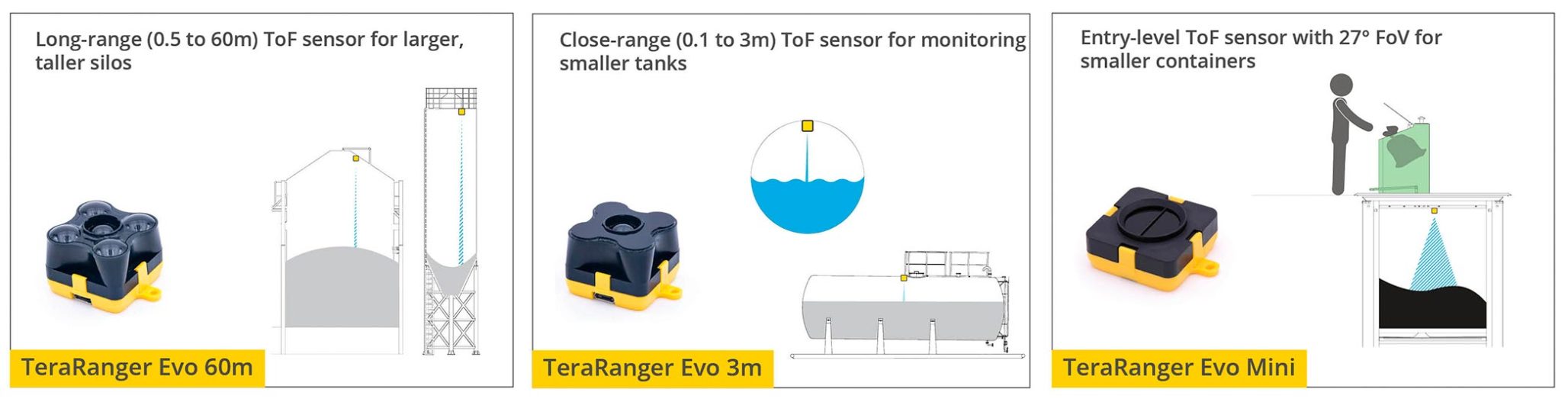

• For larger and taller silos, including animal feed bins - the long-range TeraRanger Evo 60m sensor is an ideal choice.

• For monitoring level in smaller tanks, including milk vats - Tredecile advises its close-range TeraRanger Evo 3m distance sensors.

• For smaller tanks with possible uneven surface distribution - the TeraRanger Evo Mini with its 27-degree Field-of-View will do the job!

• For larger and taller silos, including animal feed bins - the long-range TeraRanger Evo 60m sensor is an ideal choice.

• For monitoring level in smaller tanks, including milk vats - Tredecile advises its close-range TeraRanger Evo 3m distance sensors.

• For smaller tanks with possible uneven surface distribution - the TeraRanger Evo Mini with its 27-degree Field-of-View will do the job!

Self-powered, LoRaWAN level device

Meet Tredecile's pioneering LoRa Level Monitoring XL, a completely unique product designed to satisfy the needs of users across a broad spectrum of level monitoring applications. Based on a tried-and-tested Time-of-Flight LED technology, LoRa Level Monitoring XL is a wireless, self-powered and convenient to use level monitoring solution, transmitting level data directly from silos, using LoRaWAN.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.

Benefit from Tredecile’s deep expertise in sensor electronics, mechanical engineering, and software development to quickly build custom sensing solutions and address your application needs. Work with Tredecile and adapt sensor parameters to suit your application - communication (e.g LoRa), power (e.g. integrated battery), housing (IP6X rated enclosure), design (support easy installation), data output (e.g application layers), and more!

For partners looking for innovation in IoT data monitoring and digital stock management, Tredecile engages in PoC projects and pilot programs to allow access to the real potential and benefits of Time-of-Flight technology.

For partners looking for innovation in IoT data monitoring and digital stock management, Tredecile engages in PoC projects and pilot programs to allow access to the real potential and benefits of Time-of-Flight technology.