Applications - Level measurement - Level monitoring - Technology insights

Level Sensing Solutions from Tredecile

Level sensing is often described as a method of industrial process control used to determine the height of a given substance, but this definition is misleading as it denotes a singular approach.

In fact, there are numerous different techniques used to detect the levels of liquids, solids, and slurries, including:

FLOAT SWITCHES: An age-old technique for level sensing, floats detect the level of substances by the position of a buoyant device floating on the surface.

CABLE-BASED SENSING TECHNOLOGY: weight and cable-based level measurement system with physical moving parts. Inexpensive but less accurate and prone to breakdowns.

LOAD CELLS: This technique measures level variations as a function of the force that the substance exerts on its container.

CAPACITANCE SENSORS: Capacitive level sensing involves the integration of electrodes onto either the external/internal surface of a container and monitoring any changes in capacitance.

ULTRASONIC SENSORS: Higher precision than preceding techniques on this list, ultrasonic level sensing measures level in a container by emitting an ultrasonic frequency into the container headspace and calculating the strength and duration of the echo.

OPTICAL SENSORS: Ideal for real-time contactless level sensing, but the accuracy of these sensors can sometimes be inhibited by the optical properties of the measured media.

RADAR: Accurate, but costly, radar operates on a similar principle to ultrasonic level sensing but with radio waves. Interpreting radar signals to create meaningful data can be more complex than other technologies.

These are just a selection of some of the underlying technologies recommended for level sensing in applications as varied as agriculture, construction, mining, plastics, waste management, water containment, and more. As a direct result of this staggering versatility, there is no one solution to fit all level sensing problems. At Tredecile, we specialize in contactless level sensing solutions based on light-emitting diode (LED) time-of-flight (ToF) technology. In this post, we will outline the potential of Tredecile’s LED ToF sensing hardware which can serve as a technological foundation to develop specific level sensing applications.

CABLE-BASED SENSING TECHNOLOGY: weight and cable-based level measurement system with physical moving parts. Inexpensive but less accurate and prone to breakdowns.

LOAD CELLS: This technique measures level variations as a function of the force that the substance exerts on its container.

CAPACITANCE SENSORS: Capacitive level sensing involves the integration of electrodes onto either the external/internal surface of a container and monitoring any changes in capacitance.

ULTRASONIC SENSORS: Higher precision than preceding techniques on this list, ultrasonic level sensing measures level in a container by emitting an ultrasonic frequency into the container headspace and calculating the strength and duration of the echo.

OPTICAL SENSORS: Ideal for real-time contactless level sensing, but the accuracy of these sensors can sometimes be inhibited by the optical properties of the measured media.

RADAR: Accurate, but costly, radar operates on a similar principle to ultrasonic level sensing but with radio waves. Interpreting radar signals to create meaningful data can be more complex than other technologies.

These are just a selection of some of the underlying technologies recommended for level sensing in applications as varied as agriculture, construction, mining, plastics, waste management, water containment, and more. As a direct result of this staggering versatility, there is no one solution to fit all level sensing problems. At Tredecile, we specialize in contactless level sensing solutions based on light-emitting diode (LED) time-of-flight (ToF) technology. In this post, we will outline the potential of Tredecile’s LED ToF sensing hardware which can serve as a technological foundation to develop specific level sensing applications.

LED ToF Level Sensing Solutions

Optical level sensing solutions using LED involves mounting a sensor into a containment environment (silos, waste containers, etc.). The sensor emits an invisible beam of light vertically through the chamber, and an integrated photodetector obtains the reflected signal. With precise timing circuitry, the round-trip time of the signal is used to detect the vertical distance of the available headspace. With the proper algorithm development, the sensor’s distance readings could be correlated to the level of media in the container.

This simple explanation depends on the fact that free-flowing substances come to rest horizontally in containers due to gravitational force. Virtually all liquids, many slurries, and some granulated solids obey this principle. Solid materials, meanwhile, typically pile up in a peak with an angle of repose characteristic of the bulk properties, or form a funnel as they are evacuated from the container.

LED ToF sensors can be used in either area of application, but some calculations may be required to compensate for angles of repose when present, or can be solved by using multiple sensors. For solid level sensing, materials such as coal, cement, gravel, grain, malt, sand, waste and wood chips are common. While they have proven useful for liquid level sensing applications (notably opaque liquids and turbulent liquids), one must consider the potential for LED beams to penetrate through highly transparent liquid surfaces, providing unclear level measurements. With this in mind, Tredecile conducted testing in the lab, and on open-water and discovered that this characteristic was less evident than one might have imagined. You can read that report here:

LED ToF sensors can be used in either area of application, but some calculations may be required to compensate for angles of repose when present, or can be solved by using multiple sensors. For solid level sensing, materials such as coal, cement, gravel, grain, malt, sand, waste and wood chips are common. While they have proven useful for liquid level sensing applications (notably opaque liquids and turbulent liquids), one must consider the potential for LED beams to penetrate through highly transparent liquid surfaces, providing unclear level measurements. With this in mind, Tredecile conducted testing in the lab, and on open-water and discovered that this characteristic was less evident than one might have imagined. You can read that report here:

Some materials create a very dusty environment and whilst this is a potential issue, Tredecile clients have been reporting good results even when the sensors optics are dust-covered, further dispelling some of the commonly held concerns about ToF sensors for this application and helping LED ToF to rapidly set a new benchmark for efficiency and precision in challenging level sensing applications. LED ToF sensors from Tredecile provide sufficient accuracy and sensitivity whilst bringing all the advantages of a contactless level sensing solution.

Self-powered, LoRaWAN level sensing solution

Meet Tredecile's pioneering LoRa Level Monitoring XL, a completely unique product designed to satisfy the needs of users across a broad spectrum of level monitoring applications. Based on a tried-and-tested Time-of-Flight LED technology, LoRa Level Monitoring XL is a wireless, self-powered and convenient to use level sensing solution, transmitting level data directly from silos, using LoRaWAN.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.

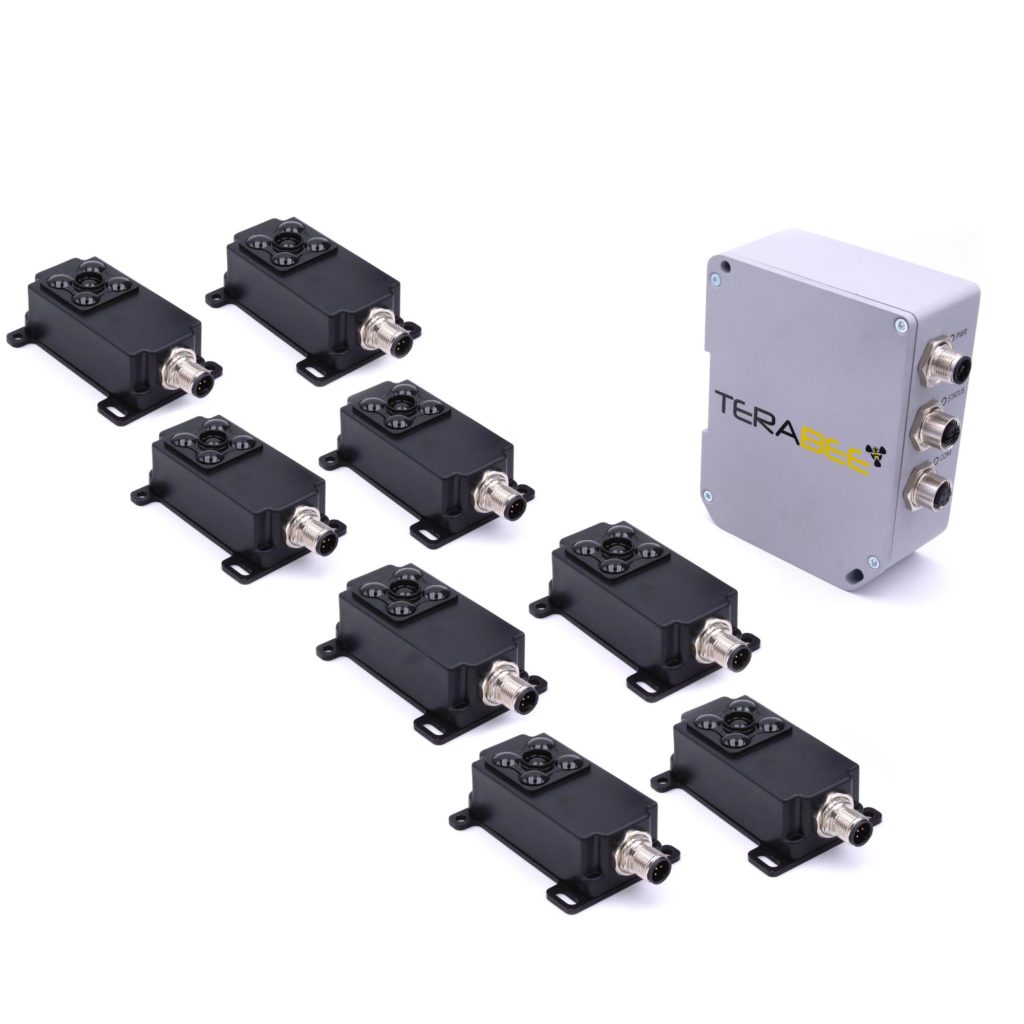

Tredecile Stock Level Monitoring System

This industrial-grade system comprises IP65-rated ToF sensors and central computing unit to provide safe, contactless fill-level measurement for silos, vats, tanks and open stockpiles.

Key benefits include:

- Contactless and eye-safe LED Time-of-Flight technology

- 60m sensor range! Ideal for tall containers

- Easily deploy one, or multiple, ToF level sensors. Take multiple measurement points in one tank, or deploy a single sensor in multiple tanks

- Computed volume and level data output via Ethernet

- Wireless access to onboard software for fast and easy system setup

Key benefits include:

- Contactless and eye-safe LED Time-of-Flight technology

- 60m sensor range! Ideal for tall containers

- Easily deploy one, or multiple, ToF level sensors. Take multiple measurement points in one tank, or deploy a single sensor in multiple tanks

- Computed volume and level data output via Ethernet

- Wireless access to onboard software for fast and easy system setup

LEVEL SENSING SOLUTIONS FOR INTEGRATION FROM Tredecile

Tredecile offers a range of high-performance and compact level sensors for monitoring stock and fill levels in silos and other containers. These are available today for order, evaluation, and OEM integration projects - with a market-leading price versus alternative measurement solutions, including ultrasound, radar, and laser.

If you are interested in using Tredecile sensing technologies to build your level sensing solution, please contact us today. We’ll be happy to explore the opportunity with you.