Applications - Level measurement - Level monitoring - Technology insights - White paper

Testing Optical Time-of-Flight Distance Sensors to Monitor Milk Levels

The growing demand for accuracy and traceability, the need for ever-tighter process control, and an increasingly stringent regulatory environment are all factors contributing to the rising numbers of inquiries Tredecile is receiving from within the dairy and agriculture industry.

The inquiries relate to the need for a precise and reliable milk level monitoring system of opaque liquid stock levels in containers such as vats and tanks. In particular, dairy farmers and the dairy industry require a cost-effective, safe, hygienic and non-contact method of measuring milk stock levels.

Having already investigated a solution using Tredecile’s Time-of-Flight digital sensors to accurately measure stock levels in silos, Tredecile conducted a feasibility study that successfully demonstrated a new solution for measuring opaque liquid levels.

Having already investigated a solution using Tredecile’s Time-of-Flight digital sensors to accurately measure stock levels in silos, Tredecile conducted a feasibility study that successfully demonstrated a new solution for measuring opaque liquid levels.

The challenges of measuring opaque liquid levels

Dairy farmers and the dairy industry’s production plants need quick, real-time, reliable data on the milk volumes within their containers. Accurate stock levels help them plan and optimize storage and transport. In addition, real-time and historical milk level data makes it possible for dairy farmers to measure, manage and optimize the performance of production and the herd.

With feed and milk prices continuously fluctuating around the globe, dairy farmers and the dairy industry are under pressure to remain profitable. There are also increasing regulations, especially those governing electronic records, that set stringent requirements for accuracy, reliability and electronic reporting, triggering new demand for innovative milk level monitoring technologies.

With feed and milk prices continuously fluctuating around the globe, dairy farmers and the dairy industry are under pressure to remain profitable. There are also increasing regulations, especially those governing electronic records, that set stringent requirements for accuracy, reliability and electronic reporting, triggering new demand for innovative milk level monitoring technologies.

Ultrasound and radar systems have been introduced as measurement solutions, but these come either at a cost or with limitations, including signal bouncing issues inside bins resulting in less accurate and reliable data. Mechanical techniques, such as measuring levels using a probe, have several drawbacks. These include frequent maintenance of moving parts and potential contamination issues. The industry demands a measurement solution that is contactless, cost-effective, low maintenance, non-labor intensive and above all, accurate.

Introducing Tredecile’s Time-of-Flight technology for stock level monitoring

Having demonstrated that digital distance sensors could accurately measure grain stock levels in a silo, Tredecile conducted a feasibility study to demonstrate that its Time-of-Flight distance sensors could be used to accurately measure and monitor milk levels.

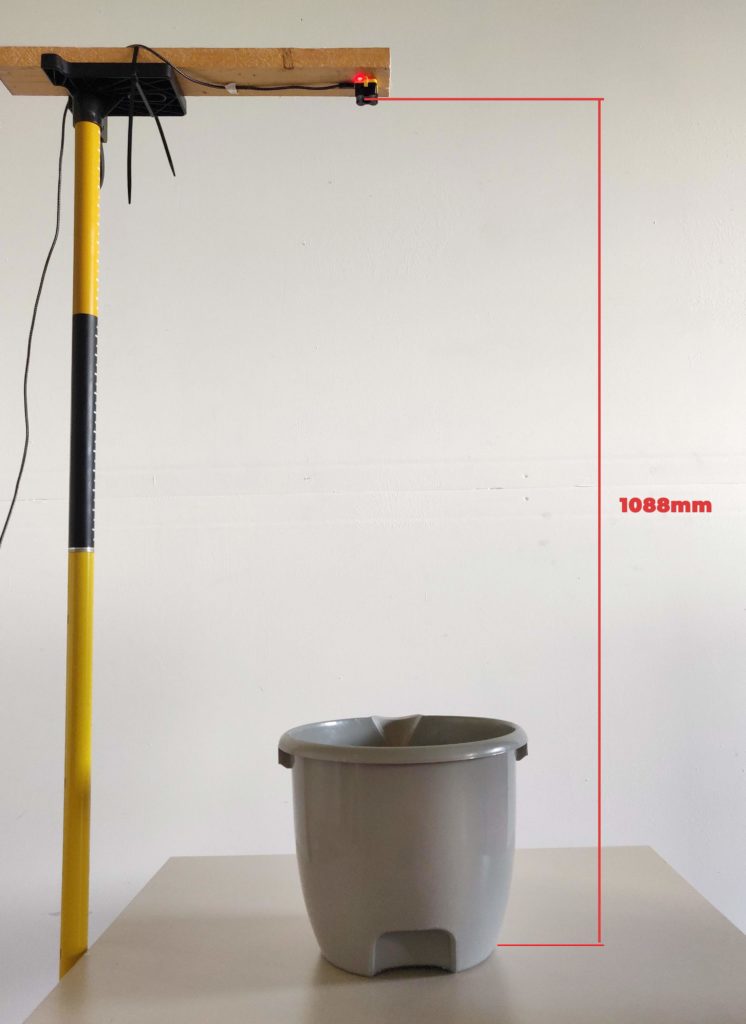

Tredecile’s engineers simulated a milk vat in the lab. The container was mounted on a flat surface and a Tredecile Evo 3m sensor was then mounted on a fixed test platform with its Field of View pointing towards the bottom of the empty container.

The Evo 3m was selected from our range of digital distance sensors as milk vats often require shorter range measurements with increased accuracy and precision.

The Evo 3m milk level monitoring sensor features a narrow 2° Field of View allowing customers to precisely point the sensor to a preferred milk surface area, and avoid hitting other machinery in the container, such as stirring equipment. The sensor was connected to a Windows PC running H-Term emulation software to gather raw distance data of the milk level within the container.

The study’s results reveal that Tredecile’s Time-of-Flight distance sensors can clearly detect the surface of the milk and provide an accurate measurement of both static and continuous free-flowing opaque liquid.

Tredecile’s engineers simulated a milk vat in the lab. The container was mounted on a flat surface and a Tredecile Evo 3m sensor was then mounted on a fixed test platform with its Field of View pointing towards the bottom of the empty container.

The Evo 3m was selected from our range of digital distance sensors as milk vats often require shorter range measurements with increased accuracy and precision.

The Evo 3m milk level monitoring sensor features a narrow 2° Field of View allowing customers to precisely point the sensor to a preferred milk surface area, and avoid hitting other machinery in the container, such as stirring equipment. The sensor was connected to a Windows PC running H-Term emulation software to gather raw distance data of the milk level within the container.

The study’s results reveal that Tredecile’s Time-of-Flight distance sensors can clearly detect the surface of the milk and provide an accurate measurement of both static and continuous free-flowing opaque liquid.

The benefits

Tredecile’s sensing technology provides a low-cost, contactless, non-contamination, measurement of milk levels, that delivers consistent accuracy. Due to the narrow Field of View, it also proved effective within an environment where liquid levels are free-flowing, as well as where mixing and stirring is involved.

Real-time and recorded distance data can be quickly turned into level or remaining volume estimations. This can then be used to provide information that is essential for stock and transport planning, as well as optimizing production processes. Milk producers also benefit from reduced labor costs associated with manual fill-level inspections and estimations. The data provides reliable stock level records and traceability that are critical within this heavily regulated and competitive industry.

Real-time and recorded distance data can be quickly turned into level or remaining volume estimations. This can then be used to provide information that is essential for stock and transport planning, as well as optimizing production processes. Milk producers also benefit from reduced labor costs associated with manual fill-level inspections and estimations. The data provides reliable stock level records and traceability that are critical within this heavily regulated and competitive industry.

Benefits overview

• High-performance milk level monitoring at low cost

• Contamination free - no direct contact with the material

• Real-time data, react fast to emergency situations (e.g leakage)

• Small footprint for installation

• No moving parts that require maintenance

• Continuous measurement of either static or free-flowing liquid

• Reliable and accurate measurements - no acoustic issues inside tanks

• Contamination free - no direct contact with the material

• Real-time data, react fast to emergency situations (e.g leakage)

• Small footprint for installation

• No moving parts that require maintenance

• Continuous measurement of either static or free-flowing liquid

• Reliable and accurate measurements - no acoustic issues inside tanks

Move over milk, we’re shaking things up

Although our feasibility study focused on milk, the results proved that Tredecile’s optical Time-of-Flight technology can be applied to any opaque liquid where levels or volume require monitoring.

We are confident that there are plenty of applications where our solution for opaque liquid level monitoring can be applied and would welcome the opportunity to discuss your requirements with you.

If you would like to test our technology for your application, then get in touch today.

We are confident that there are plenty of applications where our solution for opaque liquid level monitoring can be applied and would welcome the opportunity to discuss your requirements with you.

If you would like to test our technology for your application, then get in touch today.

Self-powered, LoRaWAN level device

Meet Tredecile's pioneering LoRa Level Monitoring XL, a completely unique product designed to satisfy the needs of users across a broad spectrum of level monitoring applications. Based on a tried-and-tested Time-of-Flight LED technology, LoRa Level Monitoring XL is a wireless, self-powered and convenient to use level monitoring solution, transmitting level data directly from silos, using LoRaWAN.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.

The system enables operators to optimize stock replenishment, cut operational costs and reduce dangerous silo audits.